Zero Liquid Discharge (ZLD)

Process :

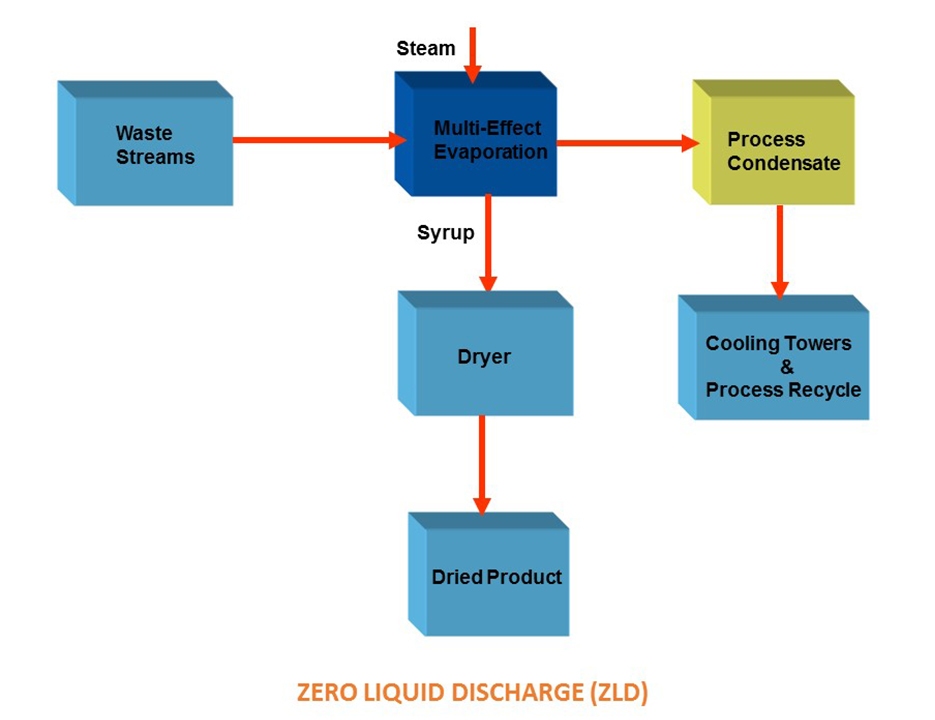

Zero Liquid Discharge (ZLD) describes a process that completely eliminates liquid discharge from a system. The goal of any well-designed ZLD system is to minimize the volume of waste water that requires treatment, process waste water in an economically feasible manner, while also producing a clean stream suitable for reuse elsewhere in the facility.

Zero Liquid Discharge (ZLD) Need

Interest in ZLD technology has grown in the industrial manufacturing sector

over the past decade. Companies are exploring to ZLD because

- Stringent waste water disposal regulations

- Company mandated green initiatives

- Public perception of industrial impact on the environment

- Concern over the quality & quantity of the water supply.

Typical Waste Streams

![]() Waste water treatment reject typically from Reverse Osmosis (RO) or Ion Exchange

Waste water treatment reject typically from Reverse Osmosis (RO) or Ion Exchange

![]() Cooling Tower & Boiler Blow Down

Cooling Tower & Boiler Blow Down

![]() Spent Coolants

Spent Coolants

![]() DI Regenerant

DI Regenerant

![]() Metal Finishing Waste waters

Metal Finishing Waste waters

![]() Tank or Equipment Washing Waste Waters

Tank or Equipment Washing Waste Waters

![]() Spent Work & Effluents From Distilleries

Spent Work & Effluents From Distilleries

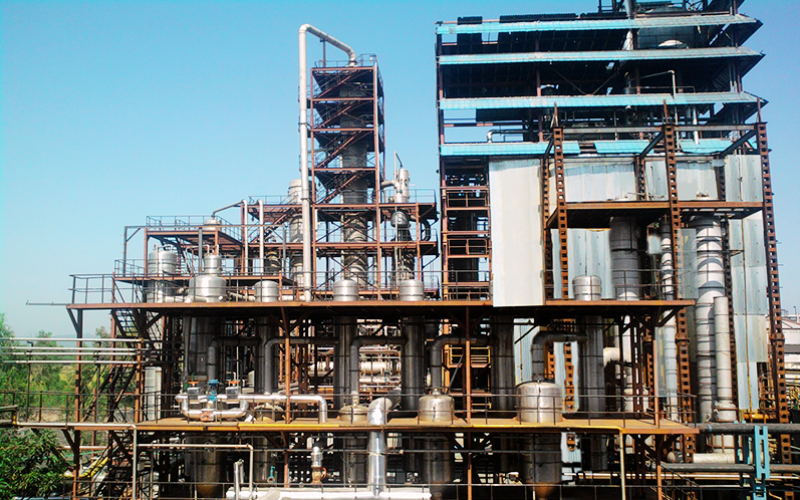

Vapco’s Approach

- Cost effective, time-tested equipment that makes it economically feasible for even moderately sized waste streams.

- Core of ZLD revolves around evaporation as it has always been “hands off” than other waste water treatment methods.

- Capabilities of handling wider range of waste streams compared to membranes and traditional physical / chemical treatment methodologies.

- Better efficiency in concentrating waste streams compared to other methods, thereby yielding a lower cost for disposal.

- Outlet streams from evaporation i.e. concentrated syrups & process condensate can further be treated in order to achieve complete ZLD system.

- Condensate obtained can be reused in process or in cooling tower as make up water thereby reducing fresh water requirements.

- Drying of syrups or rejects generated, through multiple options to reduce final effluent volumes or gain valuable by products.