Alcohol / Fuel Ethanol Plants

VAPCO provide technologies and systems for manufacturing various grades of ethanol such as Rectified Spirit, Extra Neutral Alcohol and Fuel Ethanol from varied feed stocks such as Molasses, Grains, Cane Juice and Cassava. The processes involved in any typical ethanol manufacturing plant can be categorized into two parts namely Process plant systems & Effluent Treatment plant sytems.

Effluent treatment plant systems

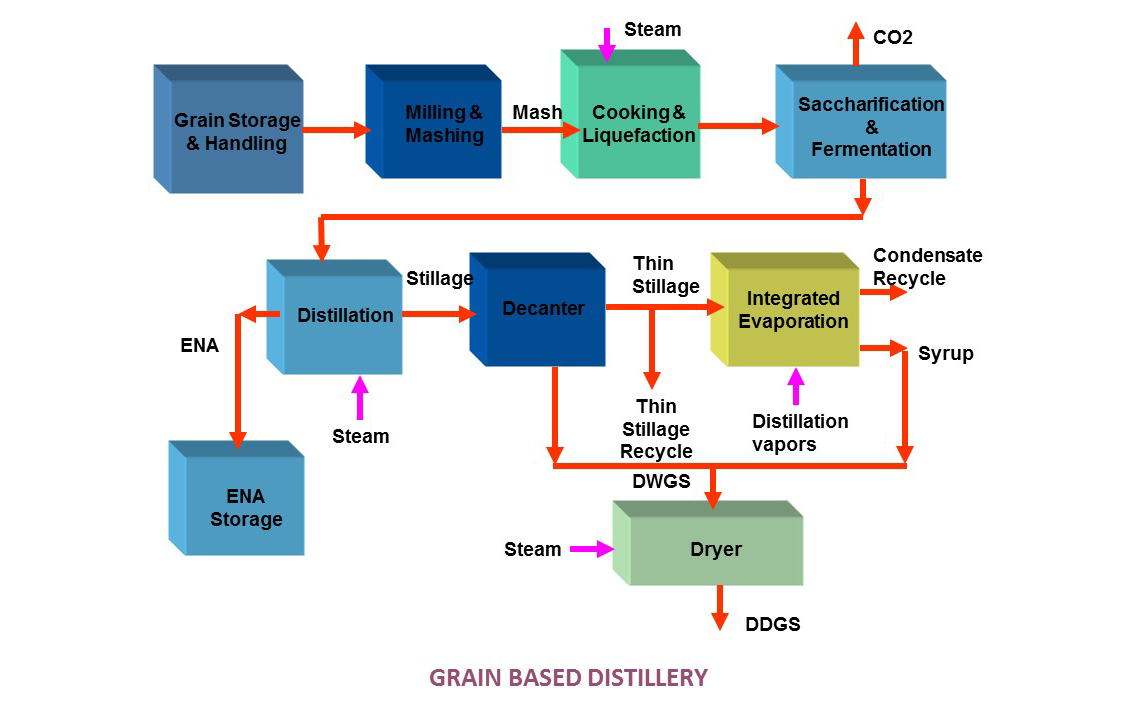

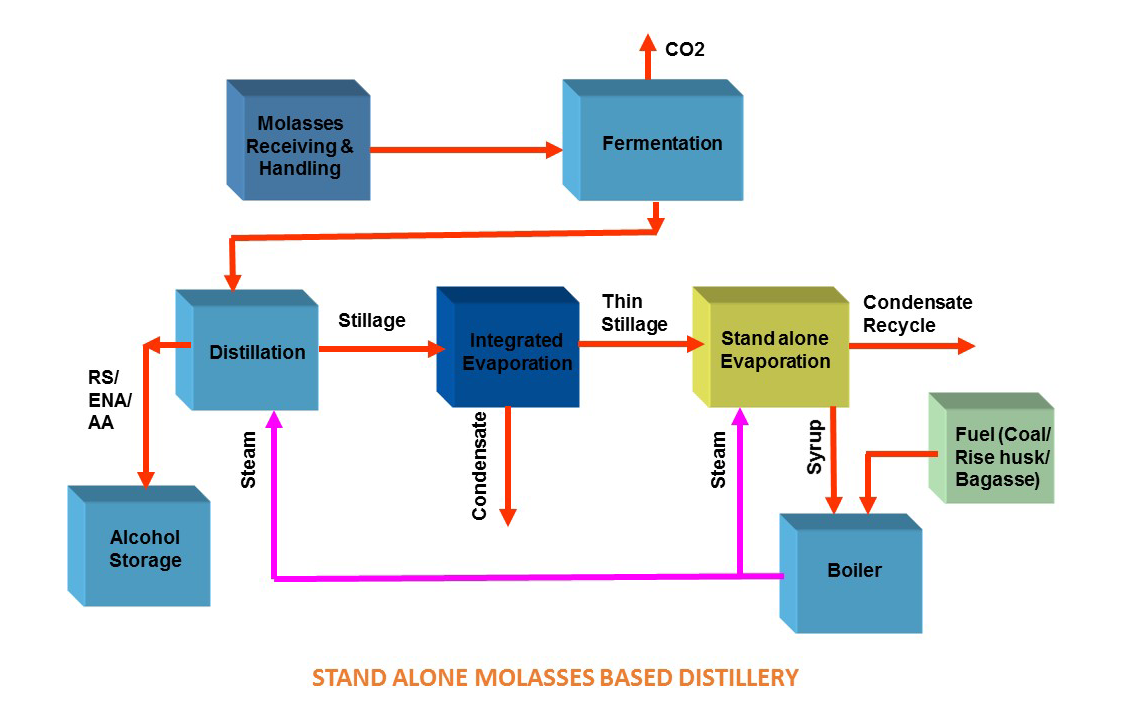

(A) For Molasses based distillery

- Bio Methanation Plant : For producing Bio Gas from waste.

- Integrated and stand alone Evaporation : For reduction in effluent volumes.

- Spent was incineration boiler : For firing the concentrated spent wash along with carrier fuel to produce steam for the complex.

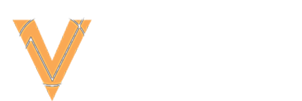

(B) For Grain based distillery

- Decantation system : For seprating wet cake and Thin slops.

- Integrated Evaporation : To recover process condensate & thick syrup which is further mixed with wet cake.

- Dryer : To abtain high quality fibrous DDGS as a byproduct, thus increasing plant profitability in environment & economical ways.

Ethanol & Bio Fuels

![]() Feed Stock Molasses

Feed Stock Molasses

![]() Feed Stock Cassava

Feed Stock Cassava

![]() Feed Stock Cane Juice

Feed Stock Cane Juice

![]() Feed Stock Grain

Feed Stock Grain

![]() Products Rectified Spirit

Products Rectified Spirit

![]() Products Extra Neutral

Products Extra Neutral

Alcohol

![]() Products Absolute

Products Absolute

alcohol

Process Plant Systems

Fermentation

To produce Fermented wash with specific alcohol concentration as the feed stock for the distillation process

Distillation

For producing Rectified Spirit and Extra Neutral Alcohol

Atmospheric Distillation

To separate crude oil into its components for further processing by other processing units.

Multi pressure Distillation

To produce international grade products viz. Industrial, potable and anhydrous alcohol.

Molecular Sieve dehydration

For Producing Fuel Ethanol